Unlock your cold

chain data

veroFresh™ creates a consolidated view of your refrigerated assets, fleet health, and energy usage, so you can proactively address potential disruptions, improve operations, and effectively compete in a digital-first, data-hungry global market.

Global traction with

the world’s leading distributors

Annual

Deliveries

Thermal Readings

Analyzed Daily

Continents

Serviced

We give you the tools to solve

complex problems

Unsure of which levers to pull to improve operations.

Limited visibility into adherence

of day-to-day SOPs.

Extensive legal and compliance requirements.

Aggressive sustainability targets but no way to track them.

Different telematics systems and separate sets of data.

Difficulty tracking the health of your fleet or ongoing maintenance issues.

Read the Case Study

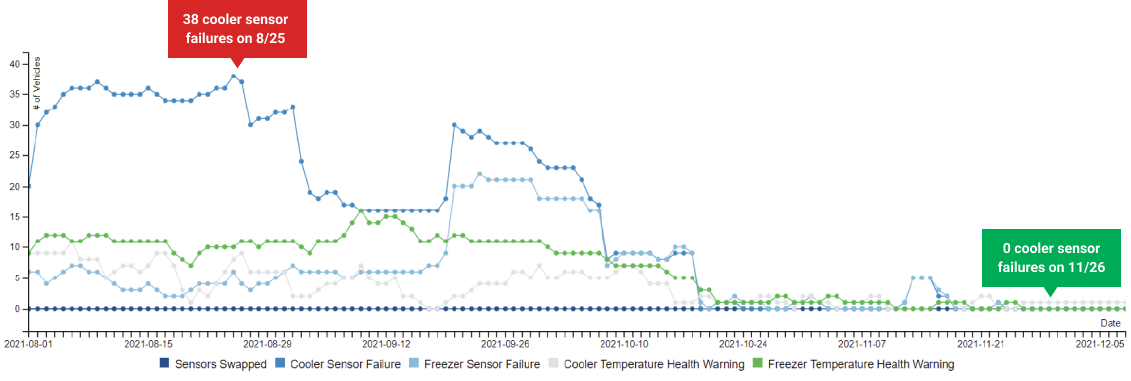

How a Cold Chain Distributor Reduced Maintenance Issues by 99% in 3 months

Read the Case Study

How a Cold Chain Distributor Reduced Audit Prep Time From Days to Minutes

SYNTHESIZE

Find signal in the noise

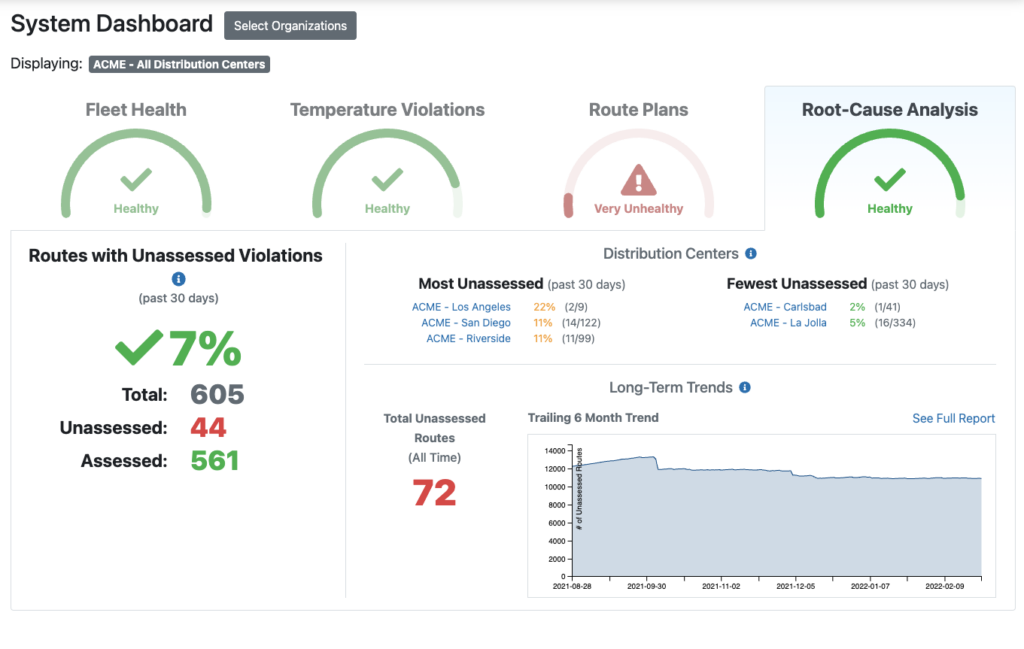

veroFresh’s™ flexible API collects and synthesizes real-time data from your disparate systems, regardless of your hardware, and simplifies it into at-a-glance dashboards and straightforward KPIs. Spot trends in your data with customizable reports that can be easily exported or pushed into a BI tool for easy sharing across your organization.

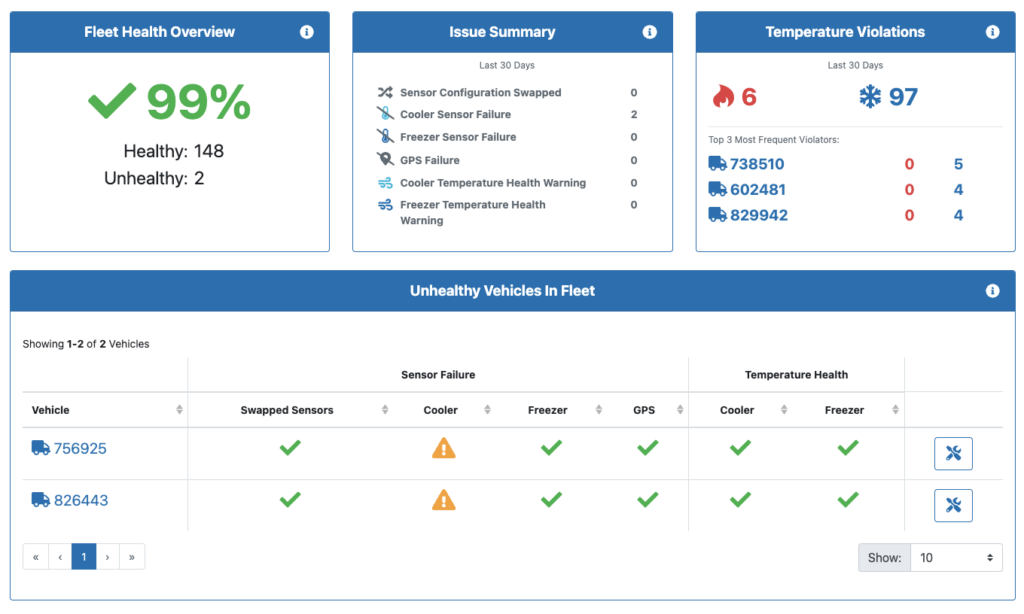

Fleet Health Overview

- Healthy (81)

- Unhealthy (7)

Issue Summary

Last 30 Days

- Sensor Configuration Swapped 0

- Cooler Sensor Failure 4

- Freezer Sensor Failure 4

- GPS Failure 0

- Cooler Temp. Health Warning 0

- Freezer Temp. Health Warning 3

Temperature Violations

Last 30 Days

25

6

- Frequent Violators

- 21400466

- 21800490

- 21400435

- Hot

- 5

- 2

- 2

- Cold

- 2

- 1

- 1

Sustainability Score

72%

Shore Power Utilization

- 36,972

- 12,162 Gallons

- 136.1 Tons/CO2

Routes Above Target

- 4,559

- 1,503 Gallons

- 16.8 Tons/CO2

veroFresh™ gives us a macro view of all of our DCs. We use it to pull best practices out of high-performing markets and apply them to under-performing markets.

Head of Network Quality

AUTOMATE

Automate compliance

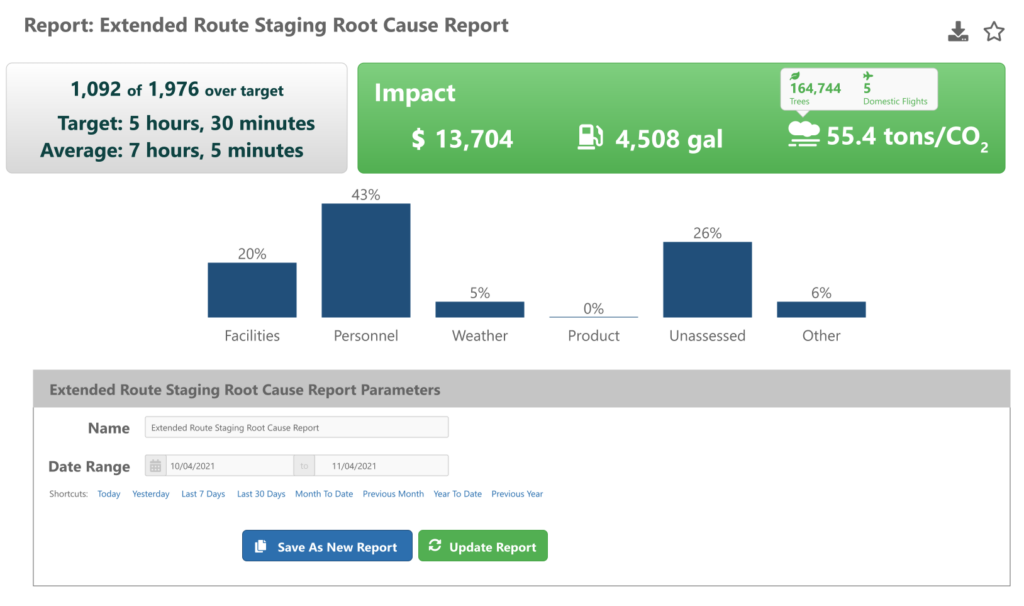

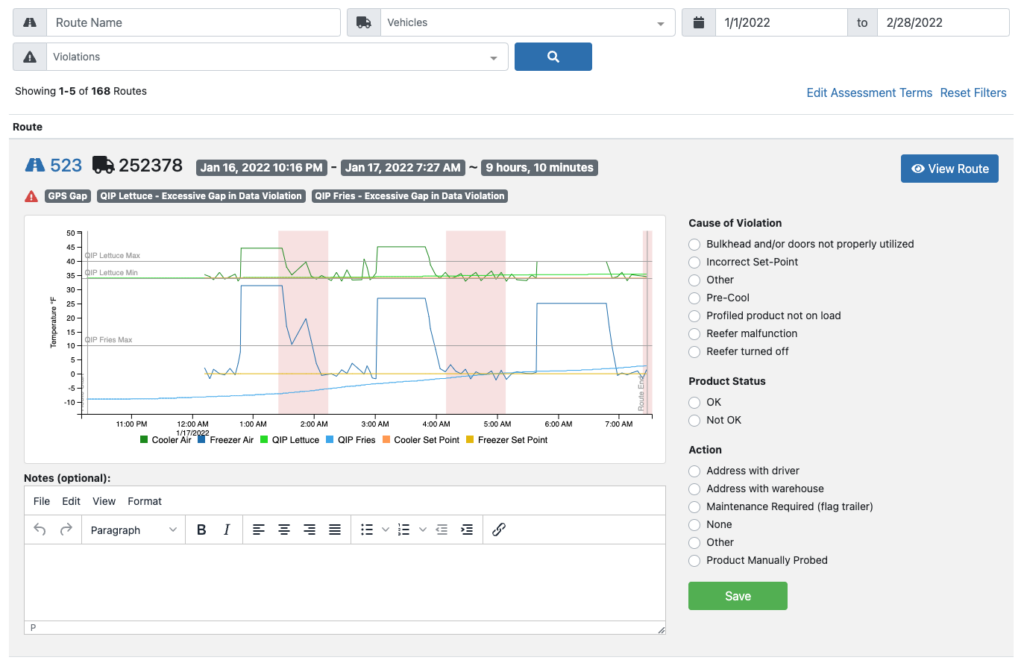

veroFresh™ automates your compliance SOPs and simplifies audits by organizing previously disconnected manual processes into a linear digital workflow. If a reefer goes out of spec, the platform records and stores the root cause of the issue, along with temperature and route information in a searchable database, giving quality, maintenance, and operations teams instant visibility into both problems and corrective action.

Root Cause Analysis

Violations last 30 days

Violating Routes

- Trailer

- 21400466

- 21800490

- 21400435

- 21201567

- 21245720

- 22400194

- Cause

- Bulkhead

- Bulkhead

- Reefer

- Pre-Cool

- Bulkhead

- Air Sensor

- Action Taken

- Address w/ Driver

- Address w/ Driver

- Maintenance

- Warehouse

- Address w/ Driver

- Maintenance

- Product

I can now supply a customer with a temperature recording in a matter of seconds, versus days or weeks.

Operations Supervisor

ACT

Take action before there’s a problem

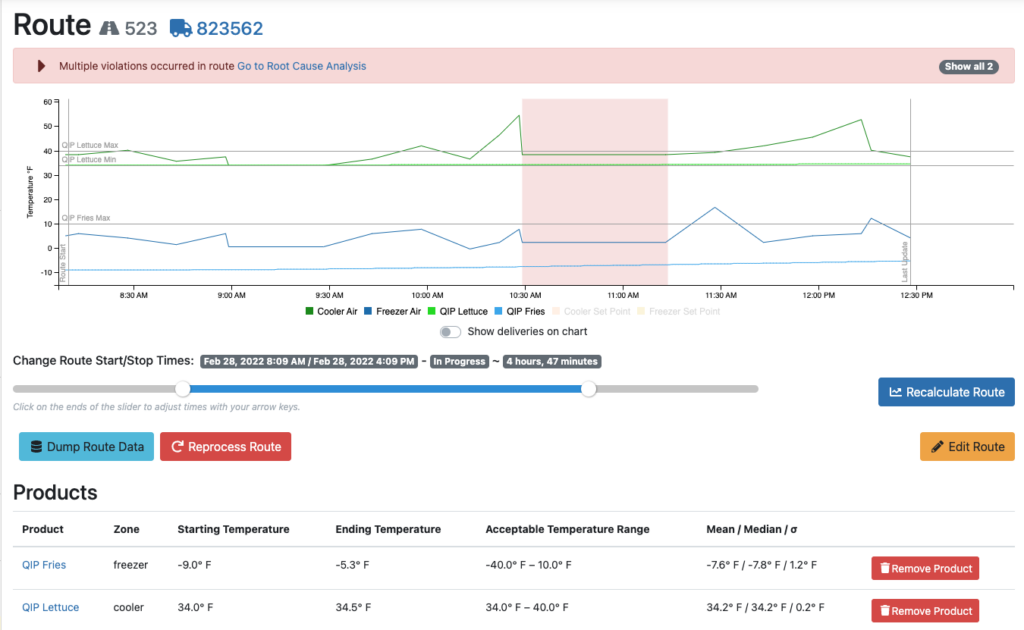

Keep your fleet operating at 100% with real-time alerts that instantly identify at-risk routes, underperforming trailers, opportunities for energy savings, unproductive drivers, and improper set points. Predictive alerts that leverage machine-learning also notify you before valuable cargo goes out of temp so you can take corrective action to minimize chargebacks and spoilage.

A global food distribution company reduced maintenance issues by 99% in 3 months

Actionable insights with

zero guesswork

Sustainability Dashboard

Coming soon! Track sustainability targets at the DC or company level in real time and surface actionable insights about how to save on energy costs.

Admin Dashboard

Simplify DC and company operations with flexible controls and permissions.

Fleet Health Dashboard

Get a bird's eye view of your entire fleet and identify underperforming trailers before they cause serious problems.

Route Information

Access real-time data on each individual route so you can better understand driver performance, route deviations, and product quality.

Root Cause Analysis

Record and store the root cause of maintenance and temperature issues in a searchable database to streamline audits and bolster compliance ops.

Pre-built integrations with

every major telematics

system

Want to see veroFresh™ in action?

Fill out the form below and one of our team members will be in touch to schedule a tailored demo.